Pure talent isn’t enough to win the Tour de France. To compete against the world’s best, you need a good team, some good luck, and a very, very good bike. For bike nerds, the Tour is the best place to see the latest and greatest bike tech in action.

The basics of a road race bike haven’t changed — two wheels, a frame, and pedals. The bicycle has evolved a lot in 120 years, but over the last 30, there have been huge leaps forward in bike design and construction. These technological shifts have shaped modern Tour de France bikes into the pedal-powered rocket ships they are today.

As we watch the Tour and ogle the flashy new bikes, let’s look back at the history behind three of the biggest technological shifts in the Tour: aerodynamics, carbon fiber, and electronic drivetrains. We’ll also take a quick peek at three pieces of new tech we’ll see on Tour de France winning bikes in the future.

[button]SHOP ROAD BIKES[/button]

The Age of Aero: Aero Road Bikes

Since the late 1800s, cyclists have understood that air resistance is the greatest force to overcome. Drop handlebars were perhaps the original aero component, allowing riders to get in lower positions. The first aerodynamic disc wheel dates all the way back to 1895. And in the early 1900s, riders were trying to set the hour record using bikes equipped with aerodynamic fairings before the UCI outlawed them.

Largely due to the UCI’s restrictive regulations, aero bike design stagnated for decades. But in the early 1970s, bike builders began experimenting with aerodynamic frame tubing and designs that could fit within the regulations.

Greg LeMond with his race-winning aero bars, aero helmet, aero frame, and Mavic Comete aero disc wheel. Photo courtesy of Mavic.

Greg LeMond with his race-winning aero bars, aero helmet, aero frame, and Mavic Comete aero disc wheel. Photo courtesy of Mavic.

Aerodynamics finally reached the tipping point in the 1989 Tour de France. American Greg LeMond trailed French rider Laurent Fignon by 50 seconds. Commentators thought this deficit was too large for LeMond to close. So, with nothing to lose, LeMond made the bold decision to put aero bars on his bike and to wear an aero helmet for the final time trial.

LeMond’s critics called these new devices ugly and unsafe, questioning if they would make any difference. But he won the stage and, more importantly, beat Fignon in the general classification by eight seconds — the smallest winning margin in history. With an average speed of 54.545kp/h (34.52mph), it was also the fastest time trial ever ridden in the Tour.

[newsletter]

This was the beginning of the aero revolution. Aero bars and aero helmets are now standard equipment in time trials.

Steel was the de facto frame material for over 100 years, but aero steel tubing never really caught on due to the cost, weight, and fabrication challenges. Manufacturers began experimenting with aluminum and carbon fiber frames that were lighter and easier to form, allowing designers to create competitive frames with deep airfoil-shaped tubes.

Bobby Julich racing on his Cervelo Soloist. Photo by: Frank Steele | Flickr Creative Commons

Bobby Julich racing on his Cervelo Soloist. Photo by: Frank Steele | Flickr Creative Commons

In 2001, Canadian brand Cervélo introduced the Soloist, which claimed to be the first, true aero road bike. With its “crushed tube” shaping, the Soloist claimed to have 4-6x less drag than traditional round-shaped tubes found on other bikes at the time. Radical geometry adjustments such as shortening the top tube while keeping a consistent seat tube angle helped the rider achieve an aero-optimized riding position as well. Until then, aero frame designs had mostly been limited to track, time trial, and triathlon bikes. In 2003. Cervélo sponsored Team CSC, and several CSC riders used the Soloist on flat stages of the Tour.

The Soloist may seem tame now, but at the time, many were shocked by the enormous three-inch-wide down tube, and the prominent airfoil tube shapes.

Not only did it have groundbreaking aerodynamics, but the early model was one of the few aluminum frames that achieved success against carbon fiber rivals, with a claimed weight of 16 pounds (more on that later). American Bobby Julich used the aluminum Soloist to win Criterium International and Paris-Nice in 2005.

[button]Shop Cervelo[/button]

Aero designs also received a boost when the UCI introduced the 6.8 kg (14.99 lb) minimum weight limit for racing bikes in 2000, still in place today. Bike manufacturers were already able to build bikes below the weight limit — the lightest frames weighed around 700g — but with the new restriction, riders couldn’t use them in competition. Thus, advantages needed to be found elsewhere. Chasing aerodynamic gains was the obvious answer.

Aero testing in the Specialized wind tunnel. Photo courtesy of Specialized.

Aero testing in the Specialized wind tunnel. Photo courtesy of Specialized.

Aero bikes like the Specialized Venge, first released in 2011, took off in popularity, especially after Mark Cavendish and Peter Sagan rode them to several stage victories in the Tour. With its “teardrop-shaped tubes” and a claimed weight of 15 pounds, thanks to FACT 11r carbon, the Venge was the company’s first aero-specific superbike.

Now manufacturers spend large amounts of time and money on computational fluid dynamics and wind tunnel testing to develop new, more slippery bikes.

“Other than fitness, aerodynamics is the most important single factor that influences your speed on a road bike,” says Mio Suzuki, Senior R&D Engineer leading aerodynamics at Specialized. “As low as 13mph you’ll begin to see speed benefits. Pros riding 20-30mph see an even bigger benefit. There's no question, [aero bikes] definitely make you faster.”

Even GC-winning all-rounders like the Specialized Tarmac and the Pinarello Dogma use extensive wind tunnel testing and aero shaping to gain a subtle advantage. With an increase in aero-optimized performance across all their road bikes, Specialized eventually dropped the Venge in their lineup as the Tarmac SL7 took over the top spot as their aero-race bike in 2022. To stay competitive in the modern Tour de France peloton, all bikes have to use some form of aero shaping.

[button]Shop Specialized[/button]

Lighter, Stronger, Faster: The Rise of Carbon

The last non-carbon tour winning bike. Photo by: Ciclismo Italia | Flickr Creative Commons

The last non-carbon tour winning bike. Photo by: Ciclismo Italia | Flickr Creative Commons

The last non-carbon bike to win the Tour de France was Marco Pantani’s aluminum Bianchi Mega Pro XL Reparto Corse in 1998. The Mega Pro XL weighed a mere 15 pounds, utilizing titanium parts and tubular wheels. For the last 20 years, carbon fiber has dominated professional cycling. Now, every bike in the Tour de France peloton is carbon, and that probably won't change.

Carbon fiber originated in the aerospace industry. It's made of loose fibers composed of carbon atoms that are suspended in resin. As mentioned earlier, carbon is a perfect material for constructing lightweight aero frames because it’s easy to form into complex aerodynamic shapes.

But there’s more to the story than that. Carbon is extremely strong for its weight, and it can be engineered to behave differently in different directions. You can design a carbon frame to be rigid in a specific direction, or rigid torsionally, while still having compliance in a different direction.

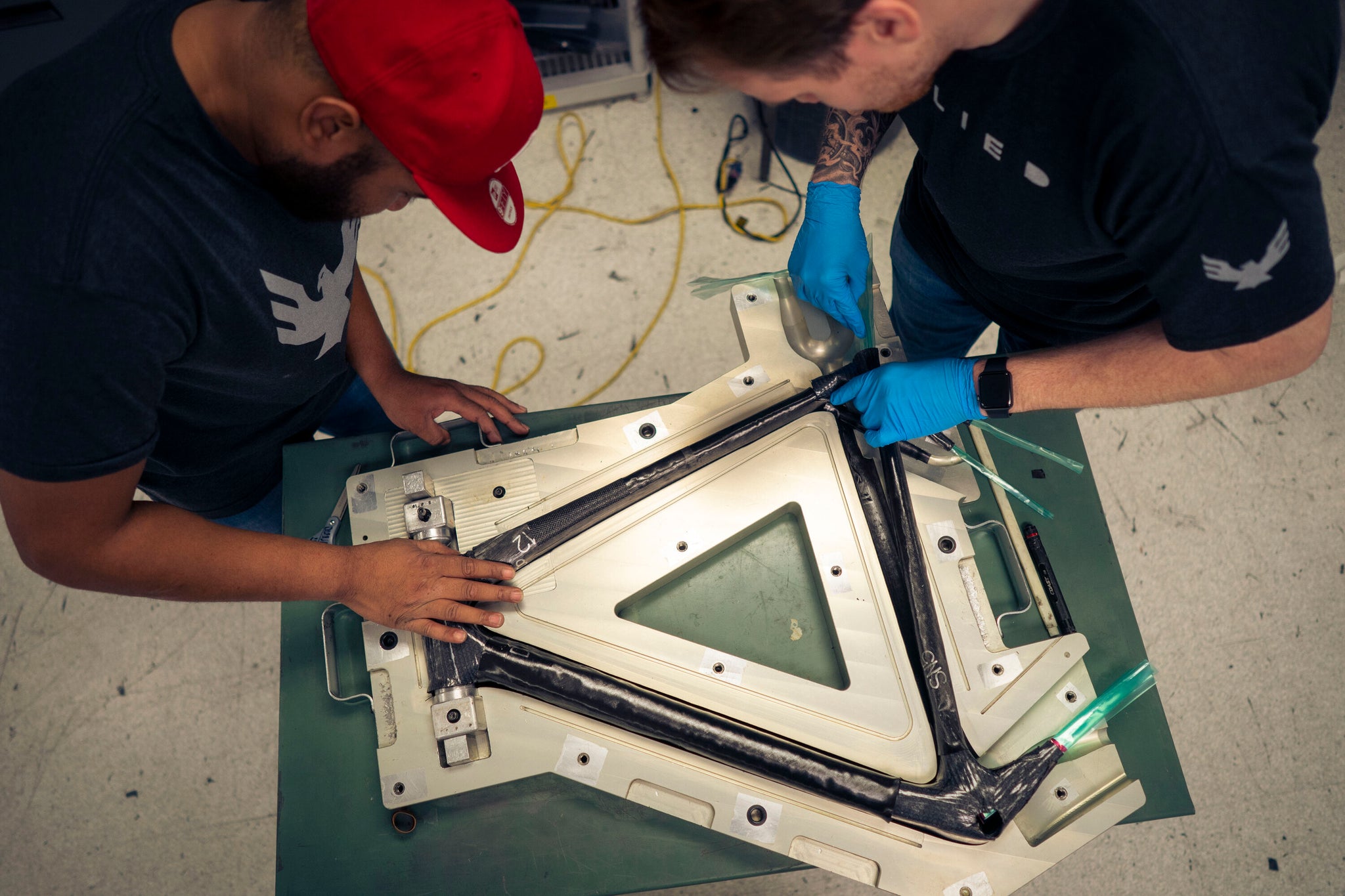

Laying carbon fiber in a frame mold. Photo courtesy of Allied Cycle Works.

Laying carbon fiber in a frame mold. Photo courtesy of Allied Cycle Works.

"There is absolutely no doubt that, as a structural material, carbon is the best one for bicycles,” says Sam Pickman, director of product at Allied Cycle Works. “If you want to change how a metal bike feels, you have very little variables to play with. You have the thickness of the material and tube size.”

“With carbon, you unlock a whole different world,” Pickman says. “What it allows you to do is change and tweak the characteristics that affect how a bike feels along the tube to hone it to do pretty much whatever you want it to do. It just gives you an unbelievable amount of control."

Carbon bikes can be designed to have desirable properties like aero shaping, light weight, and targeted stiffness, without compromising strength or comfort. Comfort may not seem like the most important trait for pro riders, but it can help riders arrive at the finish with less fatigue from road vibration and impacts. That adds up over 21 days of racing.

Bike manufacturers like Peugeot in France and Kestrel in the U.S. began experimenting with carbon frames in the early 1970s. There was a steep learning curve and it would be several years before modern monocoque frames came to market.

The Look KG 86. Photo courtesy of Look Cycles.

The Look KG 86. Photo courtesy of Look Cycles.

French manufacturer, Look, made its first carbon frame, the KG 86, with a lugged construction. The carbon tubes were made by a French company, TVT, which combined Kevlar with layers of woven carbon fiber for additional strength. The tubes were then bonded with epoxy into aluminum lugs. The KG 86 achieved legendary status when Greg LeMond (yes, LeMond again!) rode it to victory in the 1986 Tour de France. It was the first carbon bike to win the Tour. The precise quality of this 100% handmade bike made it just as good to look at as it was to ride, with the claimed weight being 16 pounds.

Steel and aluminum Pinarellos would dominate for the next decade, but after Marco Pantani’s 1998 Tour win, carbon came into fashion with the advent of Lance Armstrong. Though later stripped of his victories, Armstrong collected seven yellow jerseys aboard Trek’s OCLV carbon fiber frames. OCLV stands for “Optimum Compaction Low Void” and refers to Trek’s process of placing carbon fiber sheets into a frame mold.

A commemorative Trek 5500.

A commemorative Trek 5500.

Armstrong won the 1999 Tour on a Trek 5500. (Interesting tidbit: Thanks to Armstrong, 1999 was also the first-ever Tour victory for a Shimano-equipped bike.) Armstrong continued using Trek's 5000 series OCLV carbon frames until the carbon Trek Madone was released in 2003 (though he didn’t race it in the Tour until 2004). The first Madone had an average weight of about 16 pounds, whereas the modern Madone weighs around 17 pounds depending on the size. Increased weights can be attributed to stronger carbon fiber layups and hydraulic disc brakes, a fair trade for powerful stopping capabilities, and increased frame stiffness.

In the last 30 years, Carbon has proliferated far beyond the Tour and the bike frame into every major component of the bike in all disciplines of cycling. For example, aerodynamic carbon wheels are standard equipment for professional racers. You will see plenty of pro bikes with carbon stems, handlebars, and seatposts. Now, it’s unlikely that we will ever see a non-carbon bike win the Tour again. There is a chance though, we’ll see some new carbon composites win in the future, but more on that later.

[button]SHOP CARBON ROAD BIKES[/button]

Battery-Powered: Electronic Drivetrains

Derailleurs have been around nearly as long as the bike itself. Derailleur systems were already being designed and built in the late 1800s, but Tour de France founder Henri Desgrange didn’t allow riders to use derailleurs in the Tour until 1937. He was afraid the technology would make the race too easy. Before derailleurs, riders had two cogs on their rear hub and they had to stop and flip the rear wheel around to change their gearing.

2018 Tour winner Geraint Thomas on Shimano Dura-Ace Di2. Photo courtesy of Shimano.

2018 Tour winner Geraint Thomas on Shimano Dura-Ace Di2. Photo courtesy of Shimano.

Until very recently, all derailleurs were actuated using cables. Then, in 2009, Shimano unveiled its Dura-Ace Di2 electronic drivetrain. SunTour, Mavic, and Campagnolo had all experimented with electronic drivetrains in the ‘90s and early ‘00s. But Dura-Ace Di2 was the first commercially viable electronic drivetrain. Shimano’s Di2 groupsets radically improved shifting with only a minor weight penalty of about 80g vs their mechanical counterparts.

It ignited an electronic drivetrain revolution. Other manufacturers soon followed suit with Campagnolo releasing Super Record EPS and Record EPS in 2011, and SRAM releasing Red eTap in 2015.

For racing, electronic shifting provides a clear advantage.

“The biggest advantage is just how easy it is to shift,” says JP McCarthy, Road Product Manager for SRAM. “It may sound like a small thing, but cycling is a sport obsessed with marginal gains. Bikes are so good now that performance gains have to be squeezed out of the tiniest details. By making the act of shifting just a bit less physically or mentally demanding, an electronic drivetrain can allow riders to dedicate more focus and energy to other tasks like handling and producing power.”

A Shimano Dura-Ace Di2 front derailleur. The electric motor has made front chainring shifts more seamless and reliable. Photo courtesy of Shimano.

A Shimano Dura-Ace Di2 front derailleur. The electric motor has made front chainring shifts more seamless and reliable. Photo courtesy of Shimano.

Electronic groups also produce more consistent shifts.

“The [electric] motors on the derailleurs actuate at the same rate every time,” says Nick Legan, Road Brand Manager for Shimano North America. “You will hit the gear you want every time, perfectly. It does give you a competitive edge.”

“An electronic setup is actually exceptionally weatherproof,” says Legan. “You don’t have to worry about water, grit, and mud. As long as there's power in the battery, the shifting doesn't degrade.”

Cadel Evans rides into Paris on Shimano Dura-Ace Di2. Photo by: DancingOnThePedals.net | Flickr Creative Commons

Cadel Evans rides into Paris on Shimano Dura-Ace Di2. Photo by: DancingOnThePedals.net | Flickr Creative Commons

Despite these claims, many pros were initially hesitant to go electronic, fearing reliability issues. Then in 2011, Cadel Evans broke through. Not only did he become the first Australian to win the Tour, but he was the first to win with an electronic drivetrain. His BMC Teammachine SLR01 was equipped with Shimano Dura-Ace Di2, and he suffered no Di2-related mechanicals on his path to victory.

In 2012, Bradley Wiggins backed up this success by winning the Tour with a Dura-Ace Di2 equipped Pinarello Dogma 65.1. Amazingly, nine of the last ten Tours have been won using an electronic drivetrain (Vincenzo Nibali won in 2014 with a mechanical Campagnolo Super Record drivetrain).

With all the current Tour de France GC favorites on electronic drivetrains, it's clear that it’s the new standard.

“If you're looking for every little last performance advantage, electronic is the only way to go,” says Legan. “it is just a little bit faster, and a little consistent than a mechanical setup. At that level, it really matters.”

“The pros don't ride mechanical anymore,” says McCarthy. “At some point, you won’t see mechanical bikes winning any major races anymore.”

[button]SHOP ELECTRONIC ROAD BIKES[/button]

What to look for in future of Tour de France bikes

1x Drivetrains

My own 1x road bike.

My own 1x road bike.

I've been talking up 1x road drivetrains for years, and we've already seen them make brief appearances in 1-day races and even Grand Tour stages. The big, and most recent example that I'm thinking of is Primoz Roglic, who switched to a 1x-equipped road bike for the Stage 20 uphill time trial in the 2023 Giro d'Italia.

There will ALWAYS be 1x haters out there (plenty were quick to mock the chain drop Roglic experienced during his TT), but pro teams and racers aren't concerned with armchair engineers. They just want to go as fast as possible. In Roglic's case, he needed a bike perfectly set up to climb steep grades as fast as possible. The 1x drivetrain gave him super easy gearing, and helped him to overturn a 26-second deficit on Geraint Thomas to take the win.

Will 1x drivetrains work in every scenario? Heck no. They only make sense in purely uphill or purely flat stages (and TTs) where riders and mechanics can optimize the gearing for the stage. But since Grand Tours can be won and lost by a few seconds, it makes more and more sense to optimize bikes for single key moments. They may or may not show up in this year's Tour de France, but expect 1x road bikes to make plenty more cameos in the coming years.

Tubeless tires

Stan's NoTubes, the biggest name in tubeless sealant. Photo courtesy of stan's NoTubes.

Stan's NoTubes, the biggest name in tubeless sealant. Photo courtesy of stan's NoTubes.

In 2019, Deceuninck–Quick-Step rider Fabio Jakobsen won a stage at the Tour of California on tubeless tires. This was a historic win since tubular tires have been the standard in professional racing over 100 years. It's not just Quick-Step now. In the last 4 years, tubeless tires have made their way deeper into into the peloton.

Specialized sponsored teams like Quick-Step are using the brands super-fast S-Works Turbo RapidAir tire. The defending champs, Jumbo-Visma, along with EF Education use Vittoria's Corsa Pro G2.0 tire. Ineos and UAE, the home of two-time winner Tadej Pogacar, are riding the Continental GP 5000 S TR this year. Many teams still run tubulars, but I would bet money that this year's Tour winner will ride the majority of the stages on a tubeless setup.

Tubeless technology has already become the standard for mountain and gravel bikes, and the benefits for rolling resistance, puncture protection, and serviceability are hard to ignore. I suspect tubeless will become the top choice for top racers and the Tour de France in the near future.

[button]SHOP TUBELESS ROAD WHEELS[/button]

Graphene

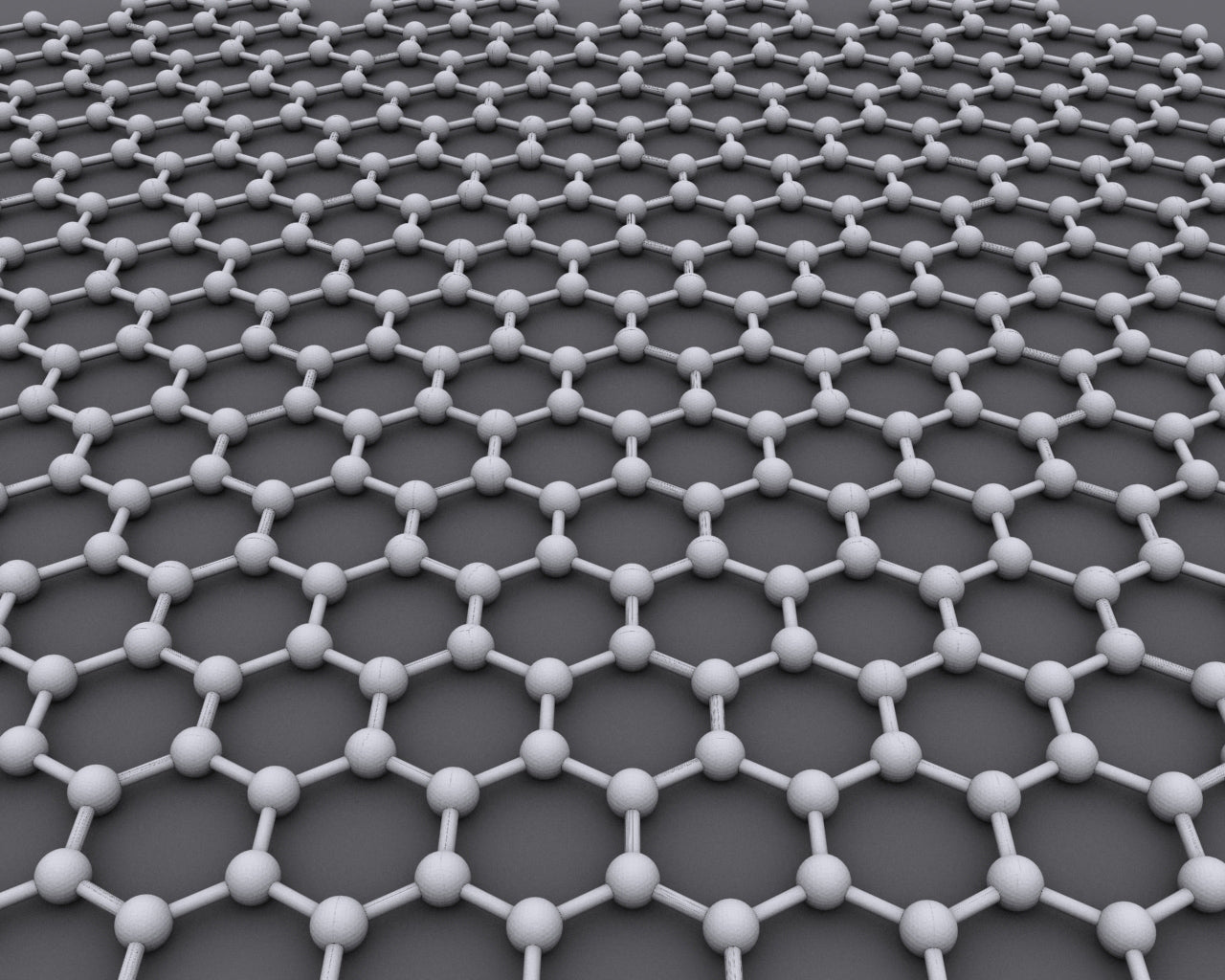

Graphene structure. Photo by: UCL Mathematical & Physical Sciences | Flickr Creative Commons

Graphene structure. Photo by: UCL Mathematical & Physical Sciences | Flickr Creative Commons

This is the big one. Graphene is a new, super-strong material that could change carbon frame construction as we know it. It’s an allotrope, or a different form of carbon (carbon can also take the form of diamond, graphite, and charcoal). Explained more simply, it is a single atomic layer of graphite arranged in a two-dimensional honeycomb lattice.

Its primary use in cycling would be as a carbon fiber additive. It improves strength because it chemically bonds to both the resin and the carbon fiber, increasing the “interfacial shear strength.” Instead of the resin and carbon fibers being separate, you get a single material that is stronger and more uniform.

Frames made using graphene will be stronger and weigh up to 50% less. Also, graphene is incredibly conductive. There is potential to build graphene circuitry into graphene bike frames so riders can have built-in electronic drivetrain wires, integrated sensors, or other electronics.

Dassi is a small British bike company (possibly defunct) experimenting with graphene composites. Photo by: DuraSport Jewel | Flickr Creative Commons

Dassi is a small British bike company (possibly defunct) experimenting with graphene composites. Photo by: DuraSport Jewel | Flickr Creative Commons

Some manufacturers are already experimenting with putting graphene in frames and other cycling components. But it will likely be several years before we see these products hit prime time in races like the Tour de France. The UCI will likely need to change its restrictive weight limit for riders and manufacturers to take full advantage of graphene.

What did I miss? What's your opinion on disc brakes and tubeless tires in the Tour? What new tech are you excited to see? Let us know in the comments!