When it comes to upgrading your bike, wheels are the first thing to consider. A good, high-quality wheelset can make even the most basic entry-level bike punch above its weight class. By reducing weight, increasing stiffness, improving tire support, and boosting aerodynamics, aftermarket carbon fiber or high-end aluminum wheels will make your bike feel fast and handle better. To understand what you're looking at when shopping for a wheel upgrade, this guide will explain how different wheel traits will affect your bike's performance.

[button]Shop all wheels[/button]

Contents

- Carbon vs. aluminum

- Weight

- Stiffness

- Rim width

- Rim depth and aerodynamics

- Durability

- Hubs and engagement

- Clincher vs. tubular vs. tubeless

Carbon vs. aluminum bike wheels

When upgrading your wheels, rim material is the first major consideration. There are two choices: carbon fiber or aluminum.

When upgrading your wheels, rim material is the first major consideration. There are two choices: carbon fiber or aluminum.

Carbon wheel pros

- Lower weight

- More stiffness

- Better aerodynamics

Carbon wheel cons

- Higher cost

- Damage requires replacement

Carbon fiber is exceptionally light, stiff, and strong. A carbon wheel is often much lighter and stiffer than a comparable aluminum wheel. The low weight and increased stiffness will improve your bike's acceleration and handling. This makes carbon the most popular option for racers or anyone who cares about performance.

Because of carbon's high strength-to-weight ration, carbon wheels can also be made deeper and wider without a major weight penalty, improving aerodynamic efficiency, handling, comfort, and rolling resistance.

The most notable downside of carbon wheels is cost. Carbon wheels are often much more expensive than aluminum wheels. Most riders can expect to spend $1,000-2,000 on a set and some top-of-the-line models can cost more than an entire bike! Fortunately, there are some solid budget carbon wheel options now on the market.

A lot of riders biggest concern with carbon wheels is durability. In general, modern carbon wheels from reputable manufacturers are very well made and can survive a lot of abuse. Many riders also report that their carbon wheels rarely need to be trued. Their stiffness and strength will keep them spinning straight for years.

If they take a harsh direct impact however, there's a chance that they can crack (carbon cracks instead of dents). If a carbon rim cracks, it becomes unsafe to ride and must be replaced.

[button]SHOP CARBON WHEELS[/button]

Aluminum wheel pros

- More affordable

- (Sometimes) More durable

- More comfortable

Aluminum wheel cons

- Higher weight

- Less stiff

Aluminum's biggest advantage is cost. Because they are so much cheaper than carbon wheels, many entry- to mid-level bikes will come from the factory with aluminum wheels.

Some riders, especially mountain bikers who are tough on equipment, prefer aluminum because is has a reputation for being more durable and robust. A strong, direct impact can cause a carbon wheel to crack, where an aluminum wheel may just end up dented. Depending on how severe a dent is, an aluminum rim can still be rideable after getting damaged. In the event that wheels get damaged beyond repair, aluminum wheels are obviously much cheaper to replace.

Aluminum rims aren't as stiff as carbon rims, which can make a bike feel less sharp when accelerating or cornering. But for some riders, that can actually be beneficial. Because aluminum rims flex more, they are more compliant and comfortable on chattery terrain, especially if you're a lighter rider.

Some racers like to train on cheaper aluminum wheels, and save their nicer carbon wheels for major events.

[button]SHOP ALUMINUM WHEELS[/button]

[newsletter]

Weight, stiffness, rim width, rim depth, and durability are the key traits that differentiate carbon and aluminum wheels, so let's take a look at each in greater detail below.

Weight

Wheels are the best place on a bike to shed grams because they are rotating weight. Increased rotating weight increases inertia. Wheel inertia matters in cycling because the rider has to pedal to overcome it — heavier wheels require more energy to accelerate.

Wheels are the best place on a bike to shed grams because they are rotating weight. Increased rotating weight increases inertia. Wheel inertia matters in cycling because the rider has to pedal to overcome it — heavier wheels require more energy to accelerate.

Upgrading to lighter wheels makes a bike feel snappier and easier to get up to speed. This is beneficial for climbing and accelerating from a stop or out of slow corners. Most riders can immediately feel a positive difference after switching to lighter wheels and it's the thing most riders pay attention to when comparing high-end wheels.

Carbon wheels are lighter than comparable aluminum wheels. This makes carbon the best option for riders who are looking for a competitive advantage to improve their climbing speed. A good set of lightweight carbon wheels can shave seconds, even minutes off a long climbing segment.

Often, the manufacturer’s claimed weight for wheels and wheelsets can differ from the actual weight on a scale. TPC weighs every wheel and wheelset and includes weight in the listings. It’s easy to use the compare tool to see which wheels are lightest.

Stiffness

Stiffer wheels make a bike feel more responsive to rider inputs like pedaling, steering, and pumping. Upgrading to stiffer wheels makes a bike accelerate more immediately, turn in more responsively, and hold lines through corners and bumps more precisely. Many rider and racers prefer stiffer wheels because this feeling of precision can improve confidence and control in high-speed situations.

Carbon wheels are stiffer than comparable aluminum wheels. Carbon fiber is naturally stiffer than metals like aluminum, and engineers also have the ability to manipulate the fiber's fabric orientation and layup to improve stiffness. Some high-end aluminum wheels are able to come close to carbon in terms of stiffness. For instance, brands like Mavic and Industry Nine use proprietary oversized spoke designs in their aluminum wheels to improve their overall stiffness.

It is possible for wheels to feel too stiff. Excess stiffness can reduce comfort, specifically in rough off-road terrain. Traditionally, aluminum wheels actually provide better ride quality because their additional flex actually helps absorb bumps.

To address that concern, many newer carbon mountain bike wheels are now prioritizing ride quality along with stiffness. Carbon can be engineered to be stiff in certain directions but compliant in other directions, so newer wheels have more vertical compliance for comfort on rough terrain while remain stiff laterally to maintain the positive steering and cornering characteristics of carbon. Personally, I still find aluminum rims feel more comfortable than the most compliant carbon rims, but that may change as carbon wheel design continues improving.

Rim width

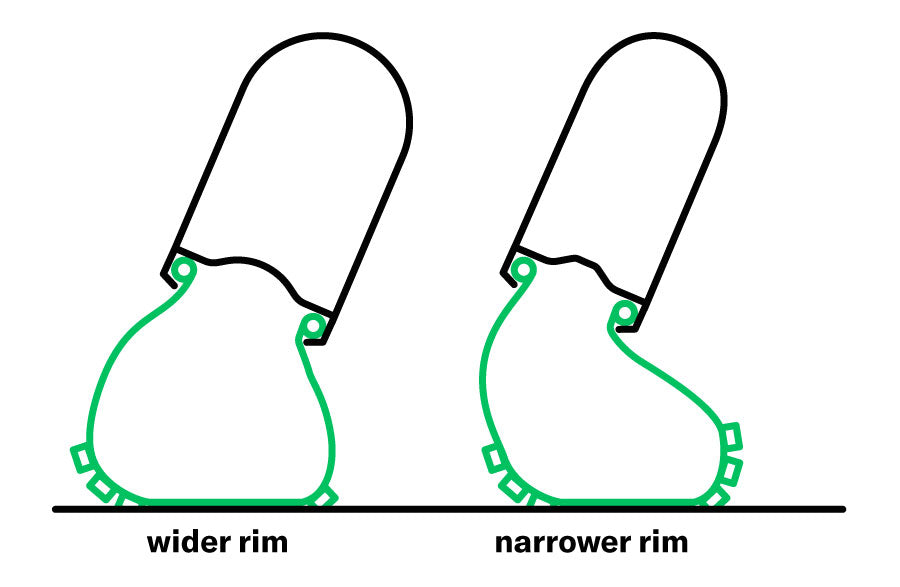

Wider tires are becoming more popular in all disciplines of cycling and modern rims are becoming wider to compliment these tires. Width is commonly measured as “internal rim width.” This is the distance between the inside of the rim walls.

Upgrading to a wider internal rim width provides more support for the tire's sidewalls. This helps improve cornering by reducing a tire's tendency to roll on the rim. The wide rim also provides additional support to the tire sidewalls at lower pressures than are possible on narrow rims.

Wider rims are ideal for off-road applications like gravel and mountain biking because wider tires and lower air pressures work together to improve overall traction and comfort. for mountain bikes, wider rims can also improve cornering speed by helping tire side knobs bite in and preventing the tire from folding or burping air under heavy cornering loads.

Road riders will also comfort and traction benefits from running wider rims. But in road cycling, external rim width is also an important consideration. Aerodynamics are a much larger concern in road cycling because the higher speeds mean riders have to exert more energy to fight air resistance. A lot of studies has been done on road bike aerodynamics, and engineers have determined an aerodynamic rule called "The Rule of 105."

The Rule of 105 states that the rim should be at least 105% the width of the tire to enable the wheel to re-capture airflow from the tire and control or smooth it as if passes over the wheel. With modern 23mm and 25mm road tires, wider external width rims around 25-28mm satisfy this The Rule of 105 and will be the best for aerodynamics.

It is possible to have a rim that is too wide for your tire. In this case, you may risk damaging your rims because your tire isn’t wide enough to adequately protect the rim walls from the road or trail surface. Or, you may square off the profile of your tires so much that it negatively affects handling and performance.

Wider rims may also be slightly heavier as they require more material than narrower rims. Choosing rim width is often a balancing act between proper tire support and desired weight.

TPC measures and lists the internal and external rim width of all wheels and wheelsets. The width of different wheels can be easily compared using the compare tool.

The table below provides very basic guidelines for what size tires pair well with which rim widths. It is possible to run a setup slightly outside the parameters and have it function well. If you are unsure if a particular rim width will be a good match with your preferred tires, check with the manufacturer, or contact our Ride Guides for assistance.

|

Internal rim width |

Ideal tire width |

|

19mm - 23mm |

25mm - 35mm Road and Cyclocross |

|

21mm - 25mm |

37mm - 45mm Cyclocross and Gravel |

|

23mm - 27mm MTB |

2.2” - 2.4” Mountain Bike |

|

27mm - 30mm MTB |

2.3” - 2.5” Mountain Bike |

|

30mm - 35mm MTB |

2.4” - 2.8” Mountain Bike |

|

35mm - 45mm MTB |

2.6” - 3.0” Mountain Bike |

To learn more about how rim width affects your ride, and what the perfect rim width is, check out our article where we asked experts from major manufacturers to explain rim width.

[button]Shop all wheels[/button]

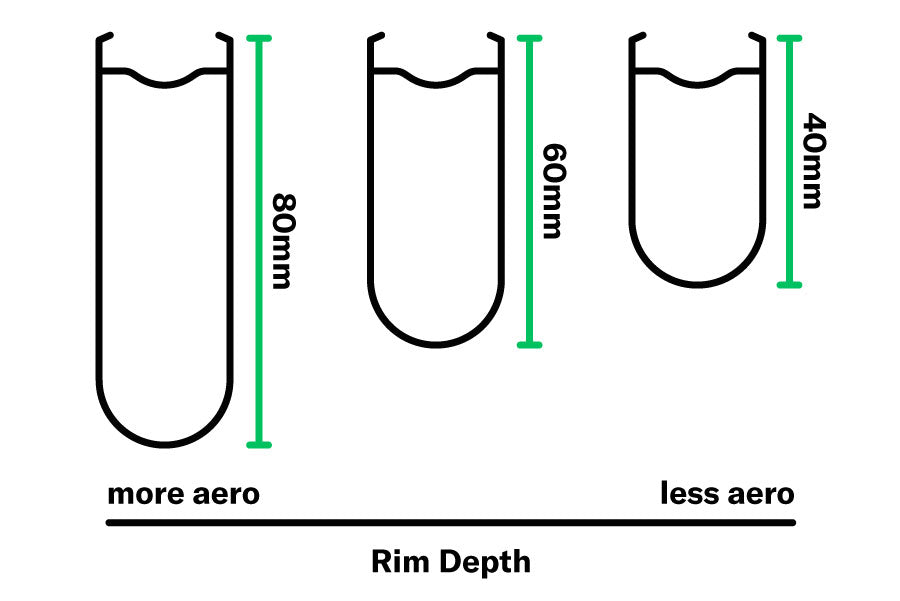

Rim depth and aerodynamics

At high speeds, air resistance is the greatest force that riders have to overcome. This is why you see road riders draft each other in groups and pacelines, and why competitive triathletes and time trialists obsessively make their equipment and riding positions as aerodynamic as possible. Wheels contribute a great deal to a bike's overall aerodynamics.

Upgrading to aerodynamic wheels with deep-section rims will help you save precious energy and ride faster on flat and rolling terrain. Generally, this is only important for road or time trial riders. Gravel and mountain bikes don't benefit from deeper rims because they travel at lower speed and use wide knobby tires that disrupt airflow.

Aerodynamics is an incredibly complicated topic that needs its own in-depth scientific article. The shape of the rim, the rim surface, the tire, spoke, and direction of wind all affect how efficient a set of wheels is. To simplify, when comparing wheels made by the same brand, a deeper rim section is generally more aerodynamic than shallow rim sections.

This is a very basic explanation, but the key to good aerodynamics is to minimize air separation over the surface of a wheel, keeping airflow attached longer. The easiest way to do this is to make a wheel deeper. By doing this you effectively make the hole inside of the rim smaller. The wheel then slips through the air more smoothly. Most triathlon and time trial riders, who prioritize aerodynamics above all else, generally use the deepest wheels possible. Some opt for solid "disc" rear wheels for better aerodynamics.

This is a very basic explanation, but the key to good aerodynamics is to minimize air separation over the surface of a wheel, keeping airflow attached longer. The easiest way to do this is to make a wheel deeper. By doing this you effectively make the hole inside of the rim smaller. The wheel then slips through the air more smoothly. Most triathlon and time trial riders, who prioritize aerodynamics above all else, generally use the deepest wheels possible. Some opt for solid "disc" rear wheels for better aerodynamics.

If you are riding at slower speeds, aerodynamics are inconsequential. Most experts estimate that the breaking point for aerodynamics is around 15kph (9.3mph). At speeds below that, wind resistance is present but not very significant.

Plus, the additional heft of deeper rims might outweigh aerodynamic benefits. Experts also say that climbs with gradients steeper than 4.5 percent favor lighter equipment versus aerodynamic gains achieved with deep rims.

Deep rims also get buffeted around in windy conditions. If you're a lighter rider or not a confident bike-handler, the squirrely feeling of an 80mm aero rim might negate any potential advantages.

Choosing rim depth is often a balancing act between aerodynamics and weight. Riders who ride steep and slow climbs will appreciate lighter wheels. But at a certain speed, and as climbs become more gradual and faster, aerodynamics will begin to play a larger role. As a general rule, the faster you’re going to ride, the deeper you want your rims.

Also, keep the rim width in mind. Most aero-focused wheels will be the ideal width to satisfy The Rule of 105. As stated above in the Rim width section, The Rule of 105 states that the rim should be at least 105% the width of the tire to enable the wheel to re-capture airflow from the tire and control or smooth it as if passes over the wheel. Most modern aero wheels are designed to be most aerodynamically efficient when paired with 23-25mm road tires.

Durability

If you buy expensive wheels, you want them to last. Durability concerns are a potential downside of carbon wheels. This is more of a concern for mountain bikers who are hard on equipment or ride gnarly or technical trails. In extreme cases, rim strikes can generate enough force to crack a carbon rim. Most carbon failures occur due to hard rim strikes or debris hitting the wheel.

Damage from rim strikes and debris occurs in cyclocross and gravel riding too, but it's slightly less common due to the nature of the terrain. It's even rarer to damage carbon wheels while road cycling.

Riders who are most concerned with durability often prefer aluminum wheels. Impacts may dent aluminum rims, but in many cases, they are still usable, despite the damage. If an aluminum wheel is totaled, it is also cheaper to replace.

In recent years, carbon technology and construction have improved. Modern carbon wheels are more durable than ever and many amateurs and recreational riders will have no issues with carbon wheel durability. The advent of tire inserts has also made carbon wheels a more viable option for more riders. Foam tire inserts protect wheels from rim strikes and can be a valuable addition to a carbon wheelset.

[product-block handle="cushcore-xc-tire-insert-set-29"/]

Plus, a number of wheel brands, such as Santa Cruz Reserve, are offering no-questions-asked lifetime warranties on new carbon wheels.

When in doubt, only purchase wheels that you can afford to replace. Plenty of mountain bikers treat their wheels as disposable commodities, making aluminum a more financially realistic choice.

Finally, if your bike has rim brakes, carbon wheels may be less appealing because wet and dirty conditions can reduce stopping power. You'll also wear through expensive brake pads more quickly. If you must ride them, consider saving carbon rims for race days and special events.

Hubs and engagement

When shopping for wheels, people often fixate on picking the right the rim, making the hubs a secondary concern. High-end hubs often weigh less and use higher quality bearings. However, it’s hard to say if the average road rider notices the difference in bearing/freehub drag or weight when comparing a mid-level hub to a high-end hub.

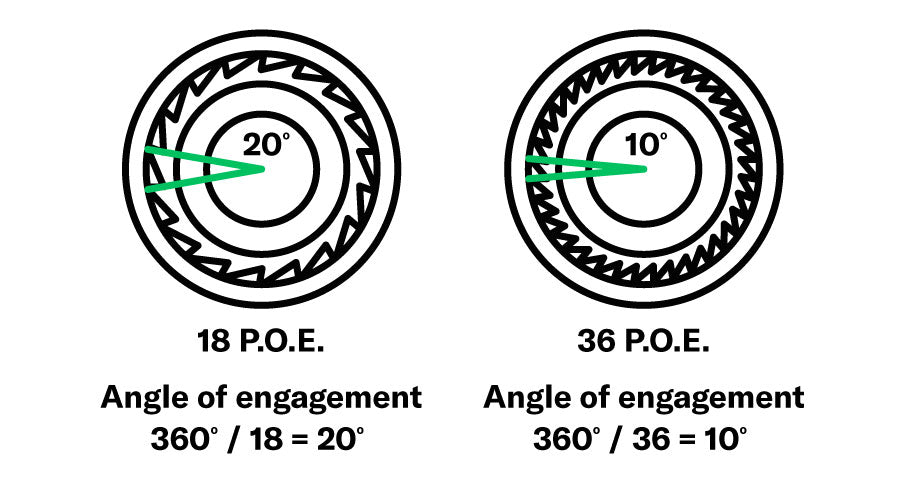

Hub engagement, on the other hand, is very noticeable and high engagement can be important for racers or riders tackling technical off-road terrain. Engagement is essentially how many “clicks” you hear when the rear wheel is freewheeling. Your bike's cassette is mounted to the hub on a freehub, which houses a ratcheting mechanism that allows the hub and wheel to continue spinning freely when you’re not pedaling.

Hub manufacturers typically employ a set of spring-loaded pawls for hub engagement. These pawls are little arms that pass over ridges that are machined inside the hub. As the hub spins forward the ridges pass smoothly over the backside of the pawls. These are the clicks you hear when freewheeling. When you pedal, the pawls spring up and bite the ridges to transfer you pedaling power.

Some hubs have more clicks than others. This is referred to as “points of engagement” (POE). This can also be referred to as degrees of engagement, which describes how far you have to rotate your crank arms in degrees before the pawls engage and drive the hub forward.

For off-road riders, faster engagement makes a difference on slow and technical features that require balance and quick, short pedal strokes. The immediate engagement can be the difference between cleaning a section and getting off to walk. Quick engagement can help in racing. You can sneak in pedal strokes while riding through choppy sections or get on the power just a split-second sooner when exiting a corner.

One of the most popular hubs comes from Industry Nine. Its new Hydra hub has an impressive 690 points of engagement. They are also popular because of the color options that allow riders to personalize their bikes. There is a multitude of other high-engagement hub options that provide competitive levels of engagement and similar good looks.

One of the most popular hubs comes from Industry Nine. Its new Hydra hub has an impressive 690 points of engagement. They are also popular because of the color options that allow riders to personalize their bikes. There is a multitude of other high-engagement hub options that provide competitive levels of engagement and similar good looks.

Clincher vs. tubular vs. tubeless

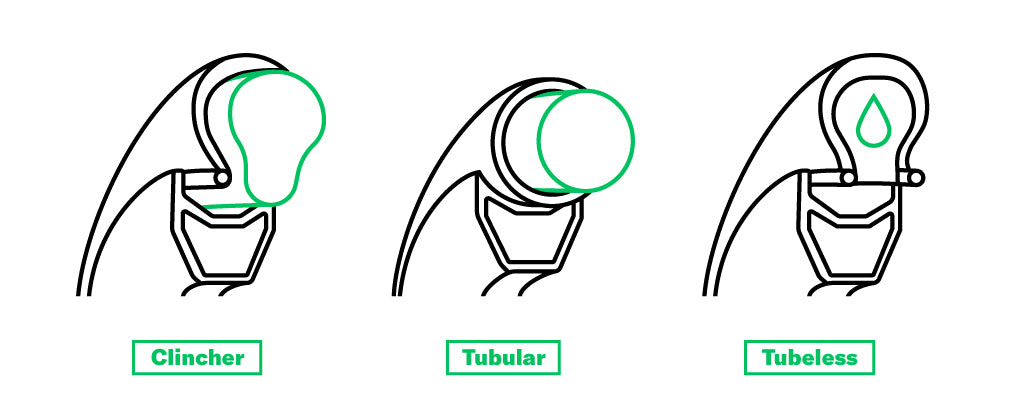

The final thing to watch out for when shopping for wheels is the rim type. There are three types available: clincher, tubular, and tubeless. If you're looking at wheels at TPC, they will be listed as one of these types. Each type of wheel is compatible with a specific type of tire.

IMPORTANT NOTE: Tubular wheels cannot be used with clincher tires or tubeless tires.

Clincher

Clincher wheels are the most common type of wheel/tire on road bikes. They use inflated rubber or latex inner tubes to support the tire. Clincher wheels and tires are less common on cyclocross bikes and mountain bikes, but some older models may still be equipped with them.

For novice mechanics, clincher wheels and tires are easy to change, repair, and maintain. Most recreational riders won’t need anything more complicated than a clincher setup.

Tubular

Tubular wheels are most often used for competitive road and cyclocross racing.

The casing and tread of tubular tires are sewn or molded around an inner tube. The tire is then glued to a tubular rim, which lacks the rim walls needed to hold the bead of a clincher tire. Some racers prefer tubular wheels and tires because they are lighter, more supple, and can have lower rolling resistance.

Tubulars are very popular among competitive cyclocross racers because they allow much lower tire pressures for maximum comfort and traction, while also being more resistant to pinch flats than clinchers.

For nearly everyone, tubulars are not ideal for training or recreational riding because they are hard to repair if you puncture. Gluing tires in your workshop isn’t too difficult, but it can be an intimidating, messy task for novice mechanics. Many riders save their tubulars for race day and ride a set of clincher or tubeless wheels day-to-day.

Tubeless

Tubeless wheels are standard equipment on most modern mountain bikes and gravel bikes. Tubeless wheels are also gaining popularity in road cycling and cyclocross as an alternative to clinchers or tubulars.

Tubeless tires are similar to clinchers but rely on an airtight seal between the bead and rim and tubeless sealant inside the tire to hold pressure. Riders can often run less air pressure in tubeless setups compared to clincher setups, improving traction and comfort. Tubeless sealant helps fix small punctures by filling holes if you strike a sharp rock or ride through thorns. This makes tubeless ideal for off-road riding where debris and aggressive riding can cause flats. In an emergency situation, a tubeless tire can also be used with a standard inner tube.

Tubeless wheels and tire systems require a little technical knowledge to install and maintain, but it's doable for most mechanics. For an in-depth explanation of what tubeless is, and how to install and maintain a tubeless system, see our Beginner’s Guide to Tubeless.

Tubeless is quickly becoming the standard across the cycling industry. If you have the option to get a tubeless or tubeless-reading wheelset versus clincher, it's the best way to go because eventually, most bikes will be tubeless.

[button]Shop all wheels[/button]

Conclusion: How to choose bike wheels

Whew! That's a lot of information. Let's boil things down to make your wheel upgrade easy (and fun!).

Use our shopping filters to whittle down TPC's wheel options based on your budget, the correct size and axle standard, and what type of tires you want to run. Then see what we've got! Personally, I ride carbon wheels on all of my bikes and strongly recommend spending a little bit extra for a nice pair of carbon wheels. If you care about performance, it'll be a worthwhile upgrade!

What do you look for in wheels? Are you a carbon or aluminum fan? Do you have an ideal wheel for you bike or style of riding? Let us know in the comments!