Ali and Frasier. Tyson and Holifield. Mayweather and MacGregor. When it comes to a heavyweight bout between lightweight carbon road wheels, Zipp and ENVE are the top contenders.

If you’re ready to turn your road bike into a high-performance machine, carbon wheels are the best starting point. And if you want some of the most desirable, best-selling wheels with industry-leading technology and quality, Zipp and ENVE are the two top choices. They are the most sought-after wheels we sell.

[button]SHOP ZIPP WHEELS[/button] | [button]SHOP ENVE WHEELS[/button]

Plenty of manufacturers make great carbon wheels, but most are made overseas. Both Zipp and ENVE manufacture their carbon rims here in the U.S. Staying American-made gives them control over the entire process through design, prototyping, testing, and production, and it helps maintain higher levels of quality control. It also allows them to quickly develop new, cutting-edge technology because they don’t have to wait for an overseas manufacturer to test ideas or make revisions. This is why Zipp and ENVE are the tech leaders for carbon wheels.

If you’re looking to upgrade to a set of Zipps or ENVEs, how do you choose which is right for you? We can't definitively answer whether one wheel manufacturer is “better” than the other (sorry). Instead, this comparison aims to explore the history of the two wheel makers, the technology they use, and the features they offer. We will also consider their popularity among our customers and employees.

Contents

History

Zipp Speed Weaponry

Zipp headquarters is within sight of the Indianapolis Motor Speedway and its story begins in motorsport. Founder Leigh Sargent cut his teeth as an engineer for the Williams Formula 1 race team in England. He moved to the U.S. to work with a CART team, and after the team folded, he stayed in Indianapolis running a shop specializing in chassis repair and carbon fiber nose boxes and wings for race cars. Until 1999, Zipp products were still manufactured and wind-tunnel tested alongside race car components.

Zipp headquarters is within sight of the Indianapolis Motor Speedway and its story begins in motorsport. Founder Leigh Sargent cut his teeth as an engineer for the Williams Formula 1 race team in England. He moved to the U.S. to work with a CART team, and after the team folded, he stayed in Indianapolis running a shop specializing in chassis repair and carbon fiber nose boxes and wings for race cars. Until 1999, Zipp products were still manufactured and wind-tunnel tested alongside race car components.

In 1988, one of Sargent’s drivers was also a cyclist. This driver brought a 3,000-gram Mavic disc wheel (cutting edge at the time) into the shop and Sargent immediately saw that he could do better. The first disc wheel he made weighed half as much as the Mavic and was constructed from Nomex honeycomb originally used for chassis tubs in race cars. After showing it off at the Interbike trade show, there was immediate interest. By 1990, he had refined it into a disc wheel weighing only 1,150 grams, which is still competitive with many modern disc wheels.

In 1988, one of Sargent’s drivers was also a cyclist. This driver brought a 3,000-gram Mavic disc wheel (cutting edge at the time) into the shop and Sargent immediately saw that he could do better. The first disc wheel he made weighed half as much as the Mavic and was constructed from Nomex honeycomb originally used for chassis tubs in race cars. After showing it off at the Interbike trade show, there was immediate interest. By 1990, he had refined it into a disc wheel weighing only 1,150 grams, which is still competitive with many modern disc wheels.

Wind-tunnel testing set Sargent’s wheels apart from the competition. With his motorsports background, it came naturally, but in the cycling world, this was still uncommon. Zipp was one of the first cycling companies to use wind drag data in product development. Today, aero testing is a cornerstone of modern road bike and wheel development.

Zipp created the first tri-spoke wheel in 1989 to give riders an aerodynamic option for front wheels. Three years later, it introduced the 2001 aero beam frameset which used a massive wing-shaped downtube, no seat tube, and a flexible beam for the top tube and saddle. Through the 1990s, these products gained a considerable foothold in the growing triathlon scene and earned Zipp a reputation as one of the most technologically progressive brands in cycling.

Zipp created the first tri-spoke wheel in 1989 to give riders an aerodynamic option for front wheels. Three years later, it introduced the 2001 aero beam frameset which used a massive wing-shaped downtube, no seat tube, and a flexible beam for the top tube and saddle. Through the 1990s, these products gained a considerable foothold in the growing triathlon scene and earned Zipp a reputation as one of the most technologically progressive brands in cycling.

Even with the great success of the tri-spoke, Zipp’s engineers weren’t satisfied. In the wind tunnel, they saw that performance could be improved with a deep-section wheel with spokes. Compared to a tri-spoke, deep-section wheels are comparably fast but less affected by crosswinds. They also pass through the air more cleanly, leaving fewer wakes and turbulent air. In 1992, the original 440 deep-section carbon wheelset went to production. Zipp’s deep-section wheels were the first of their kind and had a huge influence on aero wheel design for the years to come.

Zipp also experimented with carbon mountain bike cranks and wheels nearly a decade before they became popular. But when Zipp (the cycling company) split from Compositech (Sargent’s motorsports business) in 1998, the focus shifted to road cycling. Leigh Sargent’s original employee, Andy Ording, bought the cycling side of the business and refocused it on road development, bringing a host of new aero technology to carbon road wheels.

In 2007, component manufacturer SRAM purchased Zipp, and three years later, Zipp made history when Fabian Cancellara became the first rider to win Paris-Roubaix (and Tour of Flanders) on carbon wheels riding a prototype 303 wheelset. Victory in the most rugged WorldTour race proved that carbon wheels were the future of cycling.

[button]SHOP ZIPP WHEELS[/button]

ENVE Composites

ENVE Composites is based on the other side of the Continental Divide in Ogden, Utah. Entrepreneur Jason Schiers founded the company under the name EDGE. Before EDGE, Schiers ran a machine shop in Las Vegas making a number of custom products.

ENVE Composites is based on the other side of the Continental Divide in Ogden, Utah. Entrepreneur Jason Schiers founded the company under the name EDGE. Before EDGE, Schiers ran a machine shop in Las Vegas making a number of custom products.

Then he discovered the world of carbon fiber. Schiers did composite and laminate work for aerospace projects and NASCAR. With this inspiration, he decided to start a new company to make structural carbon parts for cars. But after spending a couple of years riding and working in the bike industry, his interests shifted toward bike components.

EDGE Composites started in 2005, stuffed in the corner of a 5,000-square-foot building that housed a long-travel dune buggy manufacturer. One day, the dune buggy owners, Brett and Taylor Satterthwaite, asked him to make custom carbon parts for their closet full of ultra-high-end mountain bikes. They became his first investors.

Eventually, the company grew to the point where it pushed the dune buggy company out, and in five short years, it had become a major player in the bike industry. Along with wheels, it began producing other components such as bars, stems, and forks.

In 2010, EDGE changed its name to ENVE Composites due to European trademark issues. Despite a great relationship with the European trademark holder, and the option for a licensing agreement, Schiers opted to let the trademark holder have the name. With business growing and a new state of the art facility in the works, EDGE transitioned into its final form and rebranded as ENVE.

That same year, the year the Zipp 303 became the first carbon wheel to win Paris-Roubaix, ENVEs DH mountain bike wheels became the first carbon wheels to win a World Cup Downhill race under Greg Minnaar. It proved to many doubters that carbon mountain bike wheels could deliver great strength and reliability at a lower weight. With its M-series and AM-series mountain bike wheels, ENVE has continued to innovate in the mountain bike space.

That same year, the year the Zipp 303 became the first carbon wheel to win Paris-Roubaix, ENVEs DH mountain bike wheels became the first carbon wheels to win a World Cup Downhill race under Greg Minnaar. It proved to many doubters that carbon mountain bike wheels could deliver great strength and reliability at a lower weight. With its M-series and AM-series mountain bike wheels, ENVE has continued to innovate in the mountain bike space.

For road wheels, ENVE brought in aerodynamicist Simon Smart, a former Formula 1 engineer, to design the next generation of aero road wheels. ENVE’s SES wheel systems now compete with Zipp’s offerings and are shaped to be aerodynamically faster and more predictable in dynamic wind conditions by controlling airflow reattachment (more on that later).

[button]SHOP ENVE WHEELS[/button]

Zipp road technology

Zipp wheel depth

|

Model: |

202 |

303 |

303S |

353 |

404 |

454 |

808 |

858 |

|

Depth: |

21mm |

40mm |

45mm |

40/45mm |

58mm |

53/58mm |

82mm |

77/82mm |

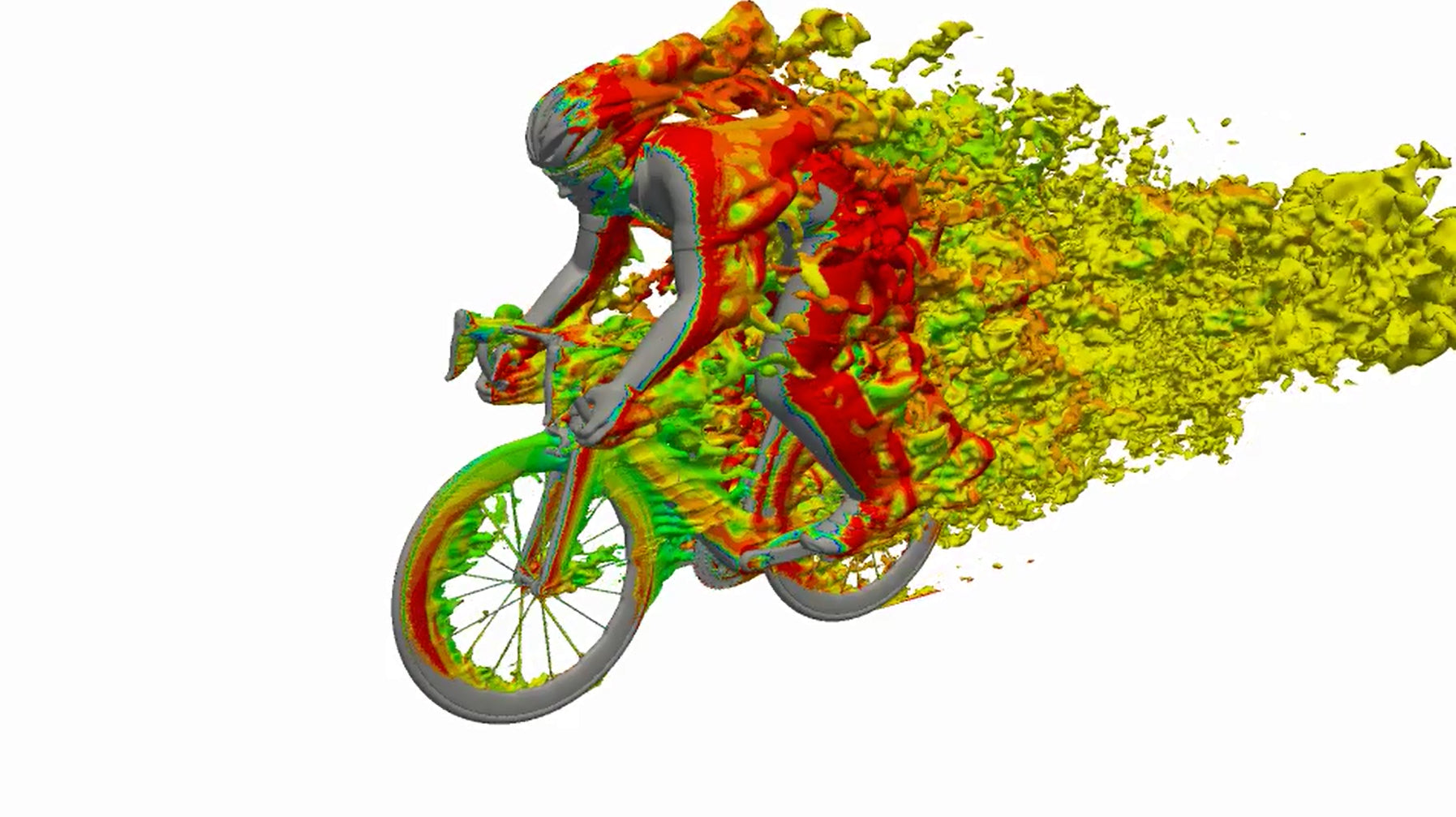

Zipp discovered in the early 1990s that the key to good aerodynamics is minimizing air separation over the surface of a wheel and keeping airflow attached for longer. The easiest way to do this is to make the rim deeper. By doing this you effectively make the hole inside of the wheel smaller so the wheel slips through the air more easily.

For Zipp’s road wheels, higher numbered model names indicate deeper section rims. Shallower rims will weigh less but are less aerodynamically efficient. In general, shallower rims are preferred for climbing due to their lighter weight. A deeper, more aerodynamic rim shines at higher speeds, usually on flat terrain.

For Zipp’s road wheels, higher numbered model names indicate deeper section rims. Shallower rims will weigh less but are less aerodynamically efficient. In general, shallower rims are preferred for climbing due to their lighter weight. A deeper, more aerodynamic rim shines at higher speeds, usually on flat terrain.

The 202, 303, 404, and 808 rim models have remained in use through every generation of Zipp rim shape from Firecrest to NSW. The 303 models are the most popular as they strikes a nice compromise between aerodynamics and weight for all-around riding.

The 454 and 858 NSW wheels have two numbers listed for depth because of their Sawtooth rim architecture.

ABLC (Aerodynamic boundary layer control)

The characteristic golf ball-like dimpling on the rim surface is a distinctive Zipp feature. A rim can only take advantage of the airflow if the air adheres to the rim surface. Airflow often becomes separated when a rim begins face airflow at an angle. This creates a vacuous region behind the rim, which causes “pressure drag.” According to Zipp, roughly 50% of real-world riding occurs with effective wind angles between 10 and 20 degrees.

The characteristic golf ball-like dimpling on the rim surface is a distinctive Zipp feature. A rim can only take advantage of the airflow if the air adheres to the rim surface. Airflow often becomes separated when a rim begins face airflow at an angle. This creates a vacuous region behind the rim, which causes “pressure drag.” According to Zipp, roughly 50% of real-world riding occurs with effective wind angles between 10 and 20 degrees.

ABLC dimples force the airflow into a higher energy state, forming a turbulent boundary layer near the surface of the rim, which allows the air to remain attached to the rim even at higher angles. This shifts the sweet spot of the rim into the ideal zone (10-20 degrees) while still reducing drag at other angles. The result is a wheel that is faster in a range of conditions.

ABLC dimples are patented to Zipp and it has developed its own special molding process in the U.S. to manufacture dimpled rims.

Firecrest rims

Zipp was one of the first to embrace the more efficient toroidal rim shape — a rounder and more blunted shape than traditional V-shaped aero rims. The Firecrest rim shape was introduced in 2010 with the new 404 Firecrest. It concentrated on aerodynamics at both the front and the back halves of the wheel. Zipp claims Firecrest was the first aero profile to effectively control airflow around the back half of the wheel. Firecrest is still in the Zipp lineup, second to the top-of-the-line NSW wheels.

Zipp was one of the first to embrace the more efficient toroidal rim shape — a rounder and more blunted shape than traditional V-shaped aero rims. The Firecrest rim shape was introduced in 2010 with the new 404 Firecrest. It concentrated on aerodynamics at both the front and the back halves of the wheel. Zipp claims Firecrest was the first aero profile to effectively control airflow around the back half of the wheel. Firecrest is still in the Zipp lineup, second to the top-of-the-line NSW wheels.

NSW rims

NSW stands for “Nest Speed Weaponry” and is Zipp’s current top-of-the-line offering. “The Nest” is the nickname for Zipp’s advanced development lab where it creates its halo-level products. Zipp’s most radical design ideas can be seen on the 454 NSW and 856 NSW wheels which use the new Sawtooth rim shape. Using the principles of biomimicry, Zipp engineers studied how nature solved problems of speed, control, and efficiency.

NSW stands for “Nest Speed Weaponry” and is Zipp’s current top-of-the-line offering. “The Nest” is the nickname for Zipp’s advanced development lab where it creates its halo-level products. Zipp’s most radical design ideas can be seen on the 454 NSW and 856 NSW wheels which use the new Sawtooth rim shape. Using the principles of biomimicry, Zipp engineers studied how nature solved problems of speed, control, and efficiency.

The examples they point to are the shape of a humpback whale’s pectoral fins and the micro texture of a shark’s skin, which allow these animals to glide effortlessly through the water. These structures inspired Zipp engineers to apply these shapes to a wheel with patented fin-shaped “Hyperfoil” nodes along the inner diameter of the rim, which form the Sawtooth profile, and “HexFin” ABLC dimples that mimic shark skin. This design reduces more aerodynamic drag and side force.

Showstopper Brake Technology

Maybe you still ride rim brakes. Carbon rims have long had a reputation for poor rim brake performance compared to aluminum rims, especially in the wet. Zipp addressed this with the Showstopper brake track, which first appeared on the 404 Firestrike rim and has become standard on current rim brake NSW rims. It uses 317 directional grooves on each side of the wheel that increase stopping power and clear water from the braking surface. Zipp claims Showstopper delivers braking force equal to aluminum rims in wet conditions. The brake track is optimized for use with Zipp’s Tangente Platinum Pro Evo Brake Pads.

Maybe you still ride rim brakes. Carbon rims have long had a reputation for poor rim brake performance compared to aluminum rims, especially in the wet. Zipp addressed this with the Showstopper brake track, which first appeared on the 404 Firestrike rim and has become standard on current rim brake NSW rims. It uses 317 directional grooves on each side of the wheel that increase stopping power and clear water from the braking surface. Zipp claims Showstopper delivers braking force equal to aluminum rims in wet conditions. The brake track is optimized for use with Zipp’s Tangente Platinum Pro Evo Brake Pads.

Cognition hubs

With the NSW generation of wheels, Zipp introduced its new Cognition hub for all NSW models. When a conventional hub is coasting, friction and drag within the freehub ratchet mechanism slow the rider down. Freehub drag can also contribute to chain-drop issues.

With the NSW generation of wheels, Zipp introduced its new Cognition hub for all NSW models. When a conventional hub is coasting, friction and drag within the freehub ratchet mechanism slow the rider down. Freehub drag can also contribute to chain-drop issues.

The rear Cognition hub solves these issues with “AxialClutch” technology. This reduces drag by completely disengaging the ratchet mechanism when coasting. It then uses magnets to re-engage it once the rider resumes pedaling.

The Cognition rear hub shell is also designed to distribute the hub flange load away from the bearings for smoother rolling bearings, regardless of spoke tension. The front hub has a unique scalloped edge hub shell design to prevent the growth of bearing bores when high radial spoke tension is applied. Zipp claims this all helps the bearings stay quieter, roll faster, last longer, and provide a laterally stiffer hub.

[button]SHOP ZIPP WHEELS[/button]

ENVE road technology

ENVE wheel depth

|

Model: |

SES 2.2 |

SES 3.4 |

SES 4.5 |

SES 6.5 |

SES 7.8 |

|

Depth (front): |

28mm |

39mm |

49mm |

60mm |

71mm |

|

Depth (rear): |

32mm |

43mm |

55mm |

67mm |

78mm |

As noted previously with Zipp, the key to good aerodynamics is minimizing air separation over the surface of a wheel. The easiest way to do this is to make a wheel deeper.

For ENVE’s SES road wheels, higher numbered model names indicate deeper section rims. SES rims feature a different depth for front and rear rims as part of their SES aero design philosophy. The SES 3.4 model is the most popular as it strikes a nice compromise between aerodynamics and weight for all-round riding.

[button]READ MORE: ENVE BUYER'S GUIDE[/button]

SES rims

ENVE introduced its new SES (Smart ENVE System) wheels in 2011. It brought on aerodynamicist Simon Smart to design, test, and validate its new wheels. Smart had 10 years of aerodynamics experience in Formula 1, and he had become a go-to consultant for cycling manufacturers. When wind-tunnel testing aero bikes for Scott and Giant, Smart started developing his own ideas for how to make the faster wheels after changing out multiple wheels during testing. He just needed a company to build them. ENVE was the ideal choice.

ENVE introduced its new SES (Smart ENVE System) wheels in 2011. It brought on aerodynamicist Simon Smart to design, test, and validate its new wheels. Smart had 10 years of aerodynamics experience in Formula 1, and he had become a go-to consultant for cycling manufacturers. When wind-tunnel testing aero bikes for Scott and Giant, Smart started developing his own ideas for how to make the faster wheels after changing out multiple wheels during testing. He just needed a company to build them. ENVE was the ideal choice.

As discussed with Zipp’s ABLC dimples, airflow that detaches is turbulent and increases drag. When there’s no wind or the wind is head-on, the goal for an aero wheel is to slice through the air with minimal drag. As the wind angle (a.k.a. yaw) increases to create a crosswind, the drag of an aero wheel will stay low as long as airflow can stay attached. Modern aero rims are shaped to keep airflow attached for as long as possible, often beyond 15 degrees. The common thinking is that the more crosswind that a wheel can handle, the faster it will be. That’s partially true, but there’s more to it than that.

For ENVE, the ultimate goal was speed on the road rather than in the tunnel. The difference is, the road is a “dynamic environment.” Even without gusts, the wind a rider encounters in the real world is constantly changing speed and direction. By contrast, accurate testing in a wind tunnel requires a static environment where the airspeed and direction are consistent.

For ENVE, the ultimate goal was speed on the road rather than in the tunnel. The difference is, the road is a “dynamic environment.” Even without gusts, the wind a rider encounters in the real world is constantly changing speed and direction. By contrast, accurate testing in a wind tunnel requires a static environment where the airspeed and direction are consistent.

In the real world, strong gusts and direction changes cause airflow to detach, and it doesn’t always reattach at the same angle at which it separated. This is called hysteresis and it can mean that the airflow remains stalled long after a gust has passed. For ENVE, the faster airflow can reattach to the rim, the faster a wheel will be. Rapid reattachment is the defining principle of the SES rim shape. To this end, ENVE has made the front and rear wheels different depths and widths to maximize each wheel's efficiency. The width and profile of the latest SES rims have also been optimized for wider tires and they are tubeless compatible.

Rapid reattachment not only improves speed but stability and rideability too. This can contribute as much to performance as pure aerodynamics. A more stable and aerodynamic wheel that is as versatile as a shallower wheel on windy days can be invaluable. ENVE claims SES wheels feel like half their depth in the wind and are easy to handle.

AR rims

ENVE AR wheels on gravel. Photo: Allied Cycle Works

ENVE AR wheels on gravel. Photo: Allied Cycle Works

Before the ENVE released its latest SES rims, ENVE produced an all-road focused line of AR rims. AR wheels had a wider internal rim width to give riders and racers an SES aero option optimized for wide 28-32mm tires. They were intended for rough and mixed surfaces like cobbles and gravel. The new SES line has been simplified, however, and standard SES rims are now designed to work with wider tires. You may still encounter AR rims in the used market though.

Textured brake track

Maybe you still ride rim brakes. Carbon rims have long had a reputation for poor braking performance compared to aluminum rims, especially in the wet. ENVE addresses this with the textured brake track found on the SES 2.2, SES 7.8, and the most recent versions of SES 3.4, and SES 4.5 wheels. ENVE claims this provides near equal wet and dry performance, better heat management, and 30% less lever force required for the same stopping power. ENVE recommends using its “black” carbon-specific brake pad designed for the textured surface.

Maybe you still ride rim brakes. Carbon rims have long had a reputation for poor braking performance compared to aluminum rims, especially in the wet. ENVE addresses this with the textured brake track found on the SES 2.2, SES 7.8, and the most recent versions of SES 3.4, and SES 4.5 wheels. ENVE claims this provides near equal wet and dry performance, better heat management, and 30% less lever force required for the same stopping power. ENVE recommends using its “black” carbon-specific brake pad designed for the textured surface.

Molded spoke holes

Look closely, and you’ll notice that, unlike most wheels, ENVE wheels don’t have visible spoke nipples. This is because ENVE chooses to use internal nipples that sit inside molded spoke and valve holes. ENVE molds rather than drills, because drilling in carbon fiber weakens that area and requires reinforcement with extra material. This adds weight and can compromise the carbon layup’s ride quality. Molded holes are more labor-intensive to manufacture but this patented feature is part of ENVE’s commitment to maximizing ride quality and durability.

Carbon Road Hub

Unlike Zipp wheels, ENVE provides multiple hub options from outside manufacturers (Zipp only uses Zipp-branded hubs). ENVE riders can use ENVE’s alloy hubs or choose to upgrade to hubs from Chris King and Industry Nine (older models also offered DT Swiss).

But riders looking for the ultimate ENVE hub option can also choose the lightweight ENVE Carbon Road Hub. The latest ENVE Carbon Road Hub builds upon the first generation carbon road hub’s legacy. The new hub shell geometry delivers 16% more lateral stiffness when compared to the first generation carbon hub shell. Additionally, the flanges of the hub have been completely redesigned to prevent premature spoke fatigue and feature a new spoke hole pattern that increases drive stiffness and reduces weight.

Low maintenance was a key objective, so the Carbon Road Hub drive system uses a DT Swiss-style, 40t ratchet. It uses high-grade custom stainless steel bearings and races to prevent corrosion in any condition or environment.

[button]SHOP ENVE WHEELS[/button]

Budget options

It’s no secret that carbon wheels are more expensive than aluminum wheels. If you want the pinnacle of carbon wheel technology, look no further than Zipp NSW or ENVE SES wheels. But the price is hard to swallow, Zipp and ENVE also offer more affordable carbon options, which will still be a noticeable improvement over stock aluminum wheels.

Zipp 302

To reduce cost, the 302 uses a smooth carbon rim that forgoes the patented ABLC dimpling used on higher-end Firecrest and NSW wheels but retains the 45mm deep toroidal rim shape. Zipp claims that depending on the conditions, yaw angle, and rider style, a dimpled 303 wheel will be on average two or three watts faster. The 302 also uses traditional hub flanges with J-bend spokes rather than the lighter and stiffer straight-pull flanges and spokes used on the Firecrest and NSW. This amounts to a 40-gram increase for the 302s compared to a set of 303 Firecrests.

To reduce cost, the 302 uses a smooth carbon rim that forgoes the patented ABLC dimpling used on higher-end Firecrest and NSW wheels but retains the 45mm deep toroidal rim shape. Zipp claims that depending on the conditions, yaw angle, and rider style, a dimpled 303 wheel will be on average two or three watts faster. The 302 also uses traditional hub flanges with J-bend spokes rather than the lighter and stiffer straight-pull flanges and spokes used on the Firecrest and NSW. This amounts to a 40-gram increase for the 302s compared to a set of 303 Firecrests.

Zipp 303 S

Zipp introduced the 303 S as the ideal wheel for riders who ride varied surfaces like rough pavement, cobbles, dirt, and gravel. It's designed specifically for tubeless disc-brake applications. The rim is 45mm deep with a wide 23mm internal rim width. Wide rims optimize tire profile to allow lower tire pressure, especially with tubeless. This increases the contact patch of the tire for increased grip and confidence when cornering, descending, and handling in wet conditions. the 303 s accommodates 28mm road tires all the up to 50mm gravel tires.

ENVE Foundation 45 and Foundation 65

ENVE’s new Foundation Collection wheels were recently released as ENVE's first lower-cost alternative. There are two Foundation road wheelsets available (disc-brake-only) — the ENVE 45 and 65, which have 45mm and 65mm depths respectively. Price is reduced by using a single rim profile front and rear (remember SES uses a different rim profile for the front and rear). They are also built with a simplified version of ENVE’s alloy disc hub and cheaper spokes. Overall, they weigh only slightly more than an SES equivalent and sacrifice a tiny bit of aero efficiency for affordability.

ENVE Foundation 45 vs. Zipp 303 S

Can’t decide between ENVE or Zipp’s budget wheels? Well, you’re not alone! Both manufacturers offer extremely high-quality options, each backed by lifetime warranties and wallet-friendly price points, so which one is for you? If the price is the main selling point, a new ENVE Foundation 45 wheelset will cost $1,750, and a Zipp 303 S wheelset will set you back $1,400, so one point goes to Zipp.

Both wheels have similar specs, but a few key differences may sway you one way. The Zipp 303 S wheelset weighs 1530g, whereas the ENVE 45’s weigh in at 1541g, not a noticeable difference by civilian standards.

Road bikes are becoming more capable with clearance for wider tires. Fortunately, the internal rim widths for both wheelsets have kept up with modern standards. The Zipp 303 S have an internal width of 23mm, which Zipp says is ideal for 28mm tires, but they’re also compatible with wider gravel tires. The ENVE Foundation wheels have a slightly narrower internal width of 21mm. ENVE states that 25-28mm tires are the best aero-optimized width.

Both wheels use center lock discs and are tubeless compatible. The Zipps use their own 76 / 176 DB hubs where ENVE has an ENVE alloy option or an Industry Nine 1/1 option. So which one is best? The Zipps are slightly more affordable, but ENVE has more options for customization. Each wheelset has 45mm rim depths, and aerodynamics will be almost identical. At the end of the day, all that matters is what will make you happiest. Let us know which one you prefer in the comments!

Popularity

Because The Pro’s Closet is the world leader in used bikes and components, including wheels, we have substantial data about what brands sell well. I dug into our wheel sales for the last 12 months and compared how many Zipp wheels we sold compared to ENVE wheels. The two are among our top-selling high-end carbon wheels (alongside Reynolds) so sales can be fairly compared to determine popularity among our customers.

I also polled riders at The Pro's Closet to see which brand they preferred between the two. Our riders love cycling, obsess over bikes, and have access to a huge selection of products so they are knowledgeable and opinionated.

The charts below show the results.

It is interesting to note that our sales figures reflect the opposite of what our poll results show. Among our customers, Zipp wheels sell twice as well as ENVEs.

It is interesting to note that our sales figures reflect the opposite of what our poll results show. Among our customers, Zipp wheels sell twice as well as ENVEs.

Zipp enjoys a lot of popularity due to its great reputation as the benchmark for aero performance. This is clear when you look at things like the Kona Bike Count. The Ironman World Championship in Kona is the biggest event in triathlon and for nearly two decades, it’s shown us the buying patterns of elite triathletes. This is meaningful to us because elite triathletes have a reputation among cyclists for an interest in performance above all else. If they’re using something, it’s because it’s been shown to work in the lab or through real-world performances. At Kona, Zipp has long been the dominant wheel choice. In 2019 it was no different with 1,596 out of 2,377 competitors using Zipp wheels. ENVE trailed behind in second with 460 competitors.

Does that mean ENVE is technologically inferior? Not at all! Keep in mind that Zipp had 15 years to establish itself in the cycling world before ENVE existed. Over the next 15 years, ENVE did a lot of catching up to reach where they are with their SES wheels. In time, the tides might shift if more riders perform well and win on ENVE products.

Looking at the sales, it’s also important to consider that mountain bike wheels make up nearly half of ENVE wheel sales at The Pro’s Closet, but only road wheels are accounted for in the sales data. For years, ENVE has made some of the most sought after mountain bike wheels on the market. Zipp only just released its 3Zero Moto mountain bike wheels in 2019. It will take time to catch up in a new genre.

Why is ENVE more popular with our riders? A lot of our younger riders seemed to prefer ENVE simply due to their aesthetic preferences. Many cited the beautiful looking logo as a reason enough to choose ENVE. Several liked that ENVE wheels had more hub options from hub specialists like Chris King, Industry Nine, and DT Swiss. Another thing to note is that many ENVE fans were also mountain bikers who were already familiar with ENVE’s mountain bike offerings.

Interestingly, it seems that many older riders (35+) at The Pro's Closet were more interested in Zipp. A couple of our former pros and industry veterans cited Zipp’s history and reputation as major factors in their decision.

Final thoughts

Zipps and ENVEs are the rare type of product I always notice when they come through the shop. Literally any bike that comes in with a pair of Zipps or ENVEs instantly earns some degree of respect. This is even more true for me if the bike’s frame is a complete beater. If I had to choose between a high-end frame and high-end wheels, I would choose wheels all day, every day. Wheels are that important to how a bike performs.

With all the technology they pack in, it’s clear that both Zipp and ENVE wheels would be a serious upgrade for any cyclist, especially those coming from stock aluminum wheels. What would I pick? I'd honestly be happy with either. But force me to choose and, right now, I’d probably jump on a pair of Zipp 454 NSW wheels for my personal bike. Why? Just look at them. They’re insane. The eye-catching Sawtooth rim profile, the intense dimpling, and the magnetic Cognition hubs all make the nerd inside me squeal with delight.

I've had a few bikes with ENVE wheels. To me they just look good.

I've had a few bikes with ENVE wheels. To me they just look good.

Saying this now is actually a surprise to me. For the longest time, I’ve loved ENVE for its aesthetics. The wheels are simply beautiful. The name, the big palindrome logos, and the beautiful carbon layup give their products an unmatched aura of refinement. In the past, I’ve used ENVE wheels on three of my own personal bikes and been extremely happy. I would use them again, but maybe I’m just looking for a change.

[button]SHOP ZIPP WHEELS[/button] | [button]SHOP ENVE WHEELS[/button]

Are you a Zipp or ENVE fan? What’s your model of choice? Or do you prefer a different wheel brand altogether? Let us know in the comments!

Photos courtesy of Zipp Speed Weaponry and ENVE Composites.

Visit our Las Vegas bike shop resource for info on bike shops, events & more in the area.