Cycling is obsessed with carbon fiber. Carbon is used to build frames, wheels, and components. You can find it on everything from entry-level bikes to barely attainable halo rides.

If you’ve spent any time talking with any opinionated cyclists, you’ve undoubtedly heard plenty of anecdotes, jokes, concerns, and criticisms about carbon as a material. The myths and stories might cause some riders to question why carbon is so popular and why it's worth considering when shopping for a new bike.

Brady Kappius of Broken Carbon and Kappius Components

Brady Kappius of Broken Carbon and Kappius Components

To learn more, we spoke to carbon fiber expert, Brady Kappius. He is the founder of Broken Carbon, a premier carbon fiber bicycle repair shop in Boulder, Colorado. Kappius and his team have successfully repaired over 4,500 carbon bike frames, and they understand the material inside and out. That’s right, despite what you might have heard, carbon fiber can be repaired. We spoke to Kappius and he helped shed some light on how carbon fiber works, why it’s so popular in cycling, and how carbon can be repaired when it breaks.

1. Why build bikes out of carbon fiber?

There’s a reason so many modern bikes are made of carbon. Carbon fiber has some advantageous properties compared to metals like steel, aluminum, and even titanium.

Brady Kappius: "Relative to other materials, carbon fiber is one of the newest in the cycling industry. The technology that brought carbon fiber to bikes really came from the aerospace industry. You didn’t really start to see carbon bikes taking off in the consumer market until the early ’90s.

"The unique thing about carbon fiber is that it's very lightweight, but it’s also durable. You can make a very, very strong bike out of carbon fiber. A huge benefit is that the material can be engineered to act differently in different directions. You can design a carbon frame to be rigid in a specific direction, or rigid torsionally, while still having compliance in a different direction. The direction you orient the fibers will determine the characteristics of a frame or component.

"Carbon fiber is pretty unique in this way. If you make a bike out of aluminum, for example, you can play with tube thickness and diameter, but not much else. Whatever the properties of the aluminum tubing are is pretty much all you’re going to get. With carbon, the engineers and manufacturers can really control the properties of the material and give different levels of stiffness and strength in different areas. Also, aluminum has what’s called an endurance limit. It doesn’t have an infinite fatigue life under normal loading conditions. Carbon has nearly infinite fatigue life.

"The properties of carbon allow a bike to made lighter. Say a particular area of a bike doesn’t see much stress. So, instead of having to use a continuous tube that’s X-thickness all the way through, you can precisely control how much fiber is placed in certain specific areas where the loads are less and concentrate more where it’s needed. This makes carbon ideal for producing a frame that’s everything you want from a bicycle — a bike that’s lightweight, durable, strong, and that rides really well."

2. How are carbon bikes made and why are they so expensive?

The big thing a lot of new riders will notice when looking at carbon bikes is that they cost more than a comparable aluminum bike. The process of making a carbon bike is more complicated than making a bike out of metal tubing, and much of that factors into the cost of carbon bikes.

Photos courtesy Allied Cycle Works. Read more about how Allied produces American-made carbon bikes.

Photos courtesy Allied Cycle Works. Read more about how Allied produces American-made carbon bikes.

BK: "The big difference between a metal bike and a carbon fiber bike is in the manufacturing process. With a metal bike, tubes are welded together. Those tubes are usually purchased or formed, and then it’s just about joining those pieces together into a frame.

"With carbon fiber, it’s completely different. Carbon fibers are literally fibers, like fabric. They’re suspended in a resin. Usually, you start with a sheet of “pre-preg” or pre-impregnated carbon fiber that already has the resin in it. Those come in a huge assortment of types depending on the characteristics you want. You might have one sheet where the fibers are oriented at a 45-degree angle, one at 0-degrees, or one where it has 90-degree fibers woven together with 0-degree fibers. Those woven fibers create that typical carbon weave look people think of when they imagine carbon fiber.

"The manufacturer chooses all of the characteristics they want out of the bike. They might want it stiffer in one spot, more compliant in another, and they correlate that to what’s called a 'layup schedule.' To get the desired properties, it requires laying the fibers in a particular place, in a particular order, and in a particular direction.

"There’s a huge amount of thought that goes into where each individual piece goes, and it’s all done by hand. A bike’s probably going to have hundreds of individual pieces of carbon fiber that have been put in a mold by hand by an actual person. A large amount of the cost of a carbon fiber bike comes from the hand labor that goes into it. The molds themselves are expensive too. It’s tens of thousands of dollars to open a single mold, and you need one for every frame size and model you’re making.

"Then the whole thing goes into an oven and gets cured. That’s when the chemical reaction happens that solidifies the whole package and makes all those individual layers come together and act coherently.

"There’s really no way to automate the whole process. Obviously, there are people out there working on it, but pretty much every carbon fiber bike and component that’s out there is still layed-up by an individual who is stacking these layers of fiber together by hand."

3. What are carbon fiber’s strengths and weaknesses?

Carbon fiber is incredibly strong. But the average consumer might have the misconception that carbon fiber is not a strong as steel, titanium, or aluminum. This isn’t always the case, but Kappius explains the reason why this sort of misconception has developed.

BK: "So, I think that carbon can be described as something that’s extremely strong and stiff. And pretty much all carbon bikes out there are made to be strong and stiff, but you need to put the asterisk on there that says, 'in normal riding conditions.' Yeah, carbon frames are awesome if you’re descending, climbing, out of the saddle, etc. All the properties of the frame are designed for that. But it’s not designed for an unusual or a catastrophic crash, or to be run into a garage door or something. Those types of forces are outside of the standard scope of use, so you don’t design a bike to see those. You could, but it wouldn’t ride as well and it’d weigh a lot more.

"Engineers are getting better at designing frames to be more durable. You are seeing it more on mountain bikes these days where manufacturers are putting more focus on areas that see higher impacts by changing the layup or the fiber type to help out with the abuse mountain bikes see. But if your 700-gram road bike frame falls over on a wooden post — well, it might crack because it’s not designed to do that. It’s designed to ride well. The vast majority of the damage we see with carbon frames is from some sort of odd instance, whether it’s a bad crash or a hit the frame has taken. It’s very rare that’s it’s from some sort of manufacturing defect."

4. What is “high-mod” carbon?

When looking at different bike frames from entry-level carbon to high-end, customers will come across terms describing carbon as “high-modulus” or "high-mod." Kappius explains what high-modulus carbon is and how much it actually matters.

BK: "Modulus is a measure of mechanical property. The modulus is the stiffness; it’s how stiff the carbon is. Theoretically, you could build a bike with only high-modulus fibers and use fewer of them, and the bike would be lighter. You see this on high-end road bikes with high-end carbon. But you don’t always want all high-modulus fibers, especially for applications like mountain biking, because high-modulus carbon is also more brittle. On mountain bikes, for example, you want some lower-modulus carbon in areas because you want the frame to take impacts better and actually have some flex to it. It’s more of a marketing term. Someone might say they have 'X-hundred Toray, high-mod whatever' carbon fiber and it really doesn’t mean as much as you think. One brand's 'high-mod' could be equivalent to another brand's low or medium-modulus carbon."

5. How can I inspect a carbon frame myself after a crash or accident?

A professional mechanic should always inspect your bike in the event of a crash or carbon damage. But if you want to do a check yourself first, here is a simple method Kappius suggests to assess any potential damage to your frame.

BK: "Crashes and damage are all relative. If it’s something like you left your bike on top of your car and drove into the garage, that’s such a crazy high force you really don’t need to bother checking it. It’s probably not even worth considering trying to ride it. We turn those bikes away, it’s just too risky. You don’t know everything that happened inside the bike.

BK: "Crashes and damage are all relative. If it’s something like you left your bike on top of your car and drove into the garage, that’s such a crazy high force you really don’t need to bother checking it. It’s probably not even worth considering trying to ride it. We turn those bikes away, it’s just too risky. You don’t know everything that happened inside the bike.

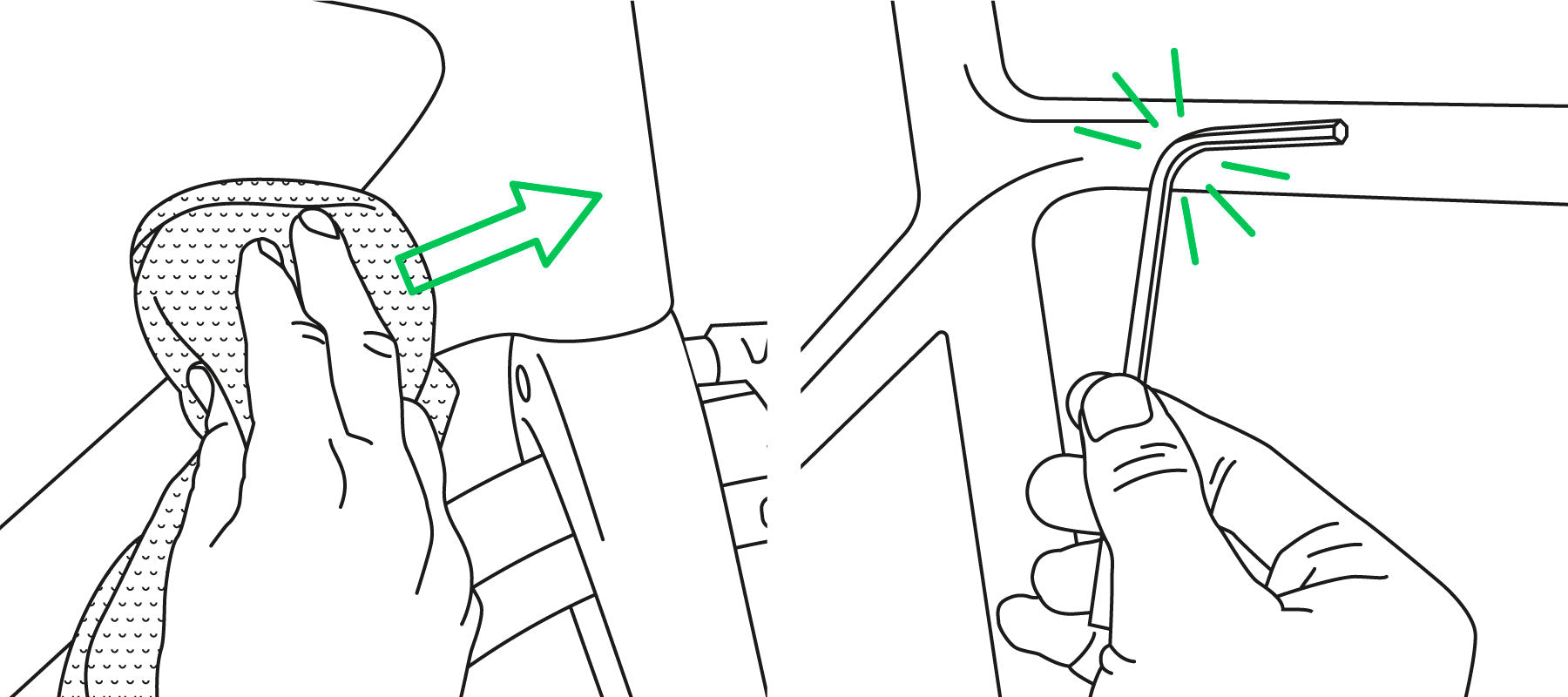

"But let’s say it's a scenario where your bike falls over, or you have a crash on your mountain bike. Hopefully, the weight behind the impact came mostly from the bike itself, or a bit of your body, but not much else. Start with a visual inspection. Wash the bike. Hopefully, you take care of your bike pretty well and you keep an eye on things so you know every scratch you’ve put into it. But clean it completely so you get a good view of the whole bike. That’s really the best place to start. You’re looking for any kind of cracks or damage. If you find something, you can run a rag over the damaged spot and if the rag snags on the carbon tube that’s a sign that there’s something wrong.

"If you do find damage like that, you can go a little bit deeper. If there’s a section of tube that has a similar shape or characteristics close by that isn’t damaged you can use it to compare. Say you have some damage a few inches behind the headtube. Check the top tube at a spot an inch or two farther down, away from the area that you’re worried about. Use your thumb and give it a press on the tube to see how it feels. Then go back to the damaged area and do the same. Does it feel softer? That’s a big indication something’s wrong.

"Then you can go on to the acoustic stuff where you do a tap test. It’s the same sort of thing. Find an area that’s away from the damage that you know is undamaged. Tap it with a metal object like a hex key and see what you hear. Then compare it to the area that you’re worried about. The tone’s going to decrease. It’ll sound high pitched if it’s good, and then kind of sound dead if it’s damaged. My guess is for the average rider, if you’ve gotten to the point where you’re going to tap test it, you probably already know it’s damaged.

"Ultimately, though, if there’s any worry about a frame you should always have it checked out by a bike shop or by us, someone who specializes in this. A lot of the time, there can be damage hidden under the paint or in areas you can’t even see.

"If you own a carbon bike just keep an eye on it. It’s different from a metal bike and it shows damage in different ways. With metal, the common things are cracks in welds or dents in tubes. Carbon doesn’t dent. It’s a very brittle material."

6. How does carbon repair work?

A lot of riders are unaware that carbon fiber frames can be repaired. Repairs performed by professionals like Broken Carbon will restore the integrity of a damaged frame and even maintain the original properties of the carbon layup.

BK: "I think in the bike industry, it’s still kind of a new idea that things like carbon frames can be repaired. As I said, composites started in aerospace. Boeing, for example, doesn’t just throw away a plane if a rock hits it and cracks something. Over the last few decades, engineers have developed a very refined and effective carbon repair process. It’s effectively what we do on bikes as well.

BK: "I think in the bike industry, it’s still kind of a new idea that things like carbon frames can be repaired. As I said, composites started in aerospace. Boeing, for example, doesn’t just throw away a plane if a rock hits it and cracks something. Over the last few decades, engineers have developed a very refined and effective carbon repair process. It’s effectively what we do on bikes as well.

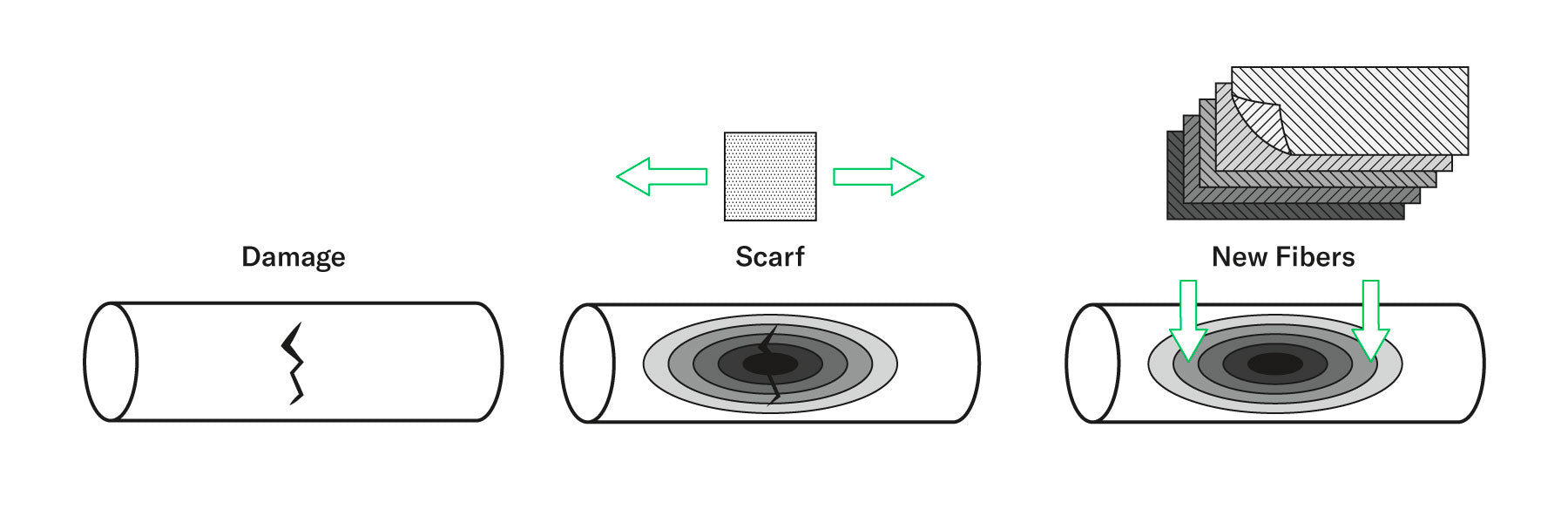

"The first steps are to get the paint off and get a better look at the carbon and get a better gauge of the damage and how far it’s propagated. Then, you remove the damaged material in a pretty particular way. It’s called scarfing. You sand it so it’s concaved and tapered out. You have to go past where it’s damaged so you can have a really good bonding area to bring in the new fibers and transfer the load. We’re tapering and bonding into existing good fibers to join it all into a rigid structure.

"As you remove the damage, you get this onion peel of carbon layers. We look at the direction or weave of the fibers and carefully match the layup of the new fibers to what was there originally. With that, you still get the same original properties of the tube with the repair.

"It’s not as simple as just wrapping more carbon around a crack. There are kits you can buy on eBay or websites to let you 'fix your carbon bike yourself.' It’s the sort of thing where you scuff up the paint and wrap some carbon around it. There’s no thought put into fiber orientation. You can change the properties of the tube and make that area so stiff that the stress concentration at the repair is greater than the tube was intended to handle and it can fail again. It’s sketchy.

7. What are the limitations of carbon repair?

Carbon repair is incredibly effective, but it can’t fix everything. Kappius explains what is outside the scope of repair.

BK: "The first thing I’ll say is that we won’t repair anything if we don’t think we can make it as strong as it originally was. That’s a big factor for us and we always err on the side of cautiousness.

"It not very common, but if there’s any worry about the alignment of the bike frame, meaning it’s no longer straight, it’s just not worth it to repair. On mountain bikes, the areas around suspension pivots where inserts are bonded during the manufacturing process are very hard to repair. And then something like a sheared-off derailleur hanger — where the hanger hasn’t just broken off but the bolts mounting it to the frame are gone — we don’t currently have a way to repair that but we’re working on it. Those are the most common limitations.

"Then there are carbon wheels. We definitely don’t repair any rim brake stuff because the braking surface has to be completely uniform for good braking and the only way to do that is out of the mold from the manufacturer. Clinchers are tough, and especially for tubeless it's tough because you can’t have discontinuities or a tire won’t seat or seal properly. Really the only wheels we consider repairing are tubular disc wheels. But most of the time it’s just not cost-effective. It’s better to get a replacement.

"One good thing is that the price of carbon wheels is coming down enough that it almost makes more sense to just get a replacement. Especially on the mountain bike side, the properties of the material and the design of the rims are getting better to handle more impacts, so we see fewer failures now."

8. How does carbon repair fit into the cycling industry?

More riders are becoming aware of carbon repair and it’s becoming an accepted practice. Kappius hopes that, in the future, manufacturers will look to repair as a way to reduce waste and keep more bikes on the road or trail.

BK: "I hope that the industry can start to accept carbon repair as a more legitimate practice. Some manufacturers do allow it and are willing to work with us. It would avoid a lot of waste because there really aren’t good options for recycling. Damaged carbon just goes into the landfill.

"We always tell a customer, if you can get your bike warrantied, go for it. We’re not just going to take your money because we can. Unfortunately, oftentimes, a damaged frame might be totally fixable and usable, but the manufacturer will want the frame chopped or destroyed. A bike will still have so much use left in it. It’s sad that’s the route they take, but I understand from a liability standpoint why they do it.

"It’d be great to have to opportunity to go to manufacturers and show them what we’re doing, and that the properties of the frame are all the same. Instead of spending a few grand on a new frame you could spend a few hundred dollars.

"All of our repairs have a fully transferrable five-year warranty. We stand behind our work and don’t make repairs unless they’re going to be as strong as new. If it a frame that obviously still has significant value then it makes sense to repair it. Customers shouldn’t have any second thoughts about riding a repaired bike from us."